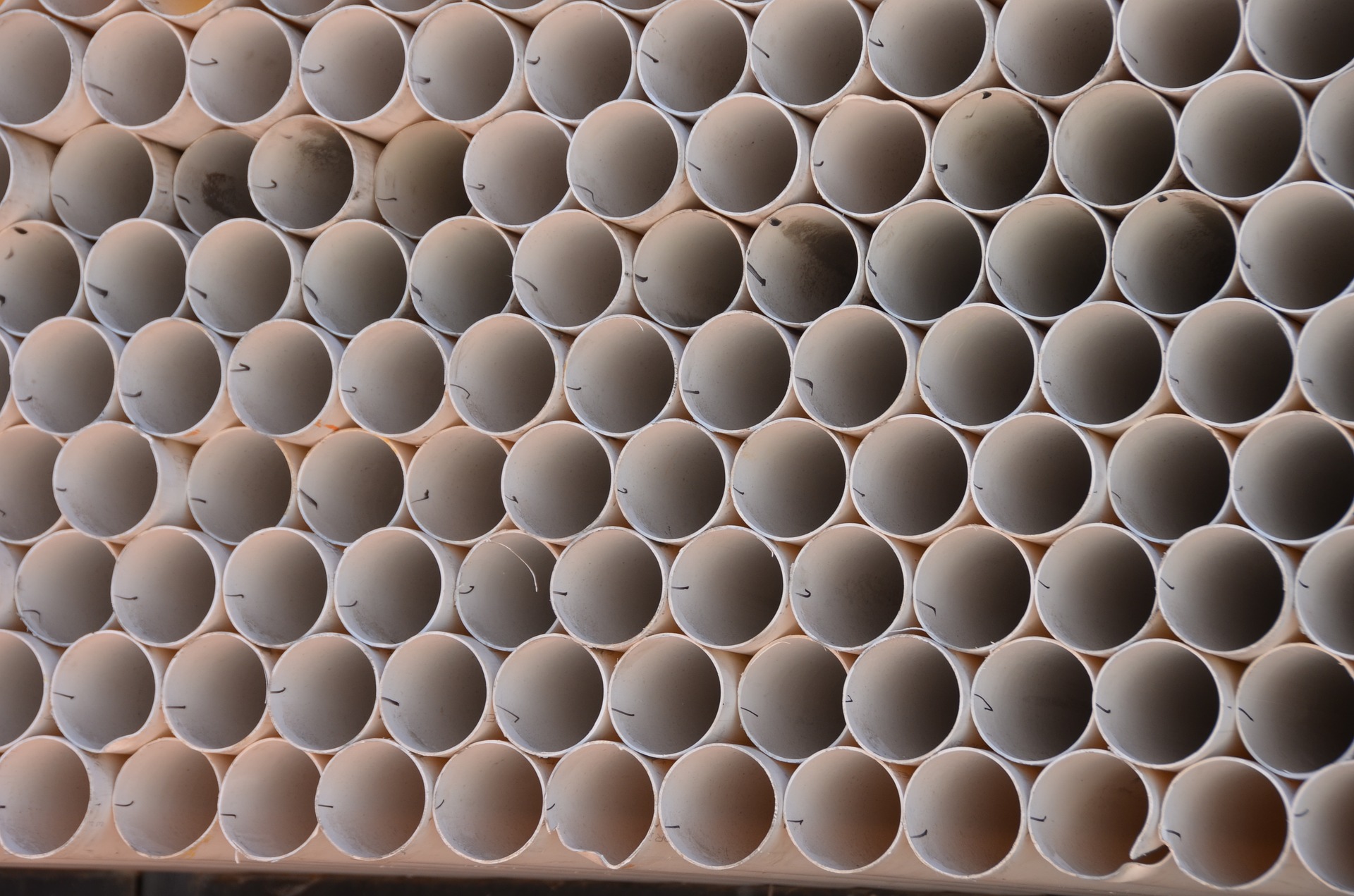

PVC Waterstop – the best solution to concrete construction

When most construction professionals think of a ‘waterstop,’ they commonly refer to a ribbed profile extrusion of thermoplastic or rubber material. Waterstops are materials embedded in the concrete, with the purpose of blocking the passage of water through the joint.

To choose a waterstop that is suitable for your project’s waterproofing needs, it is vital to know the various product types and material compositions. Most varieties are manufactured exclusively for use in cast-in-place concrete construction joints, while some types can also be used with expansion joints. Moreover, there are some types of waterstops that must accommodate the expected lateral, transverse, and shear joint movements, as well as, the expected hydrostatic pressure.

Since the 1950s, the most commonly used waterstop is PVC (Polyvinyl Chloride). Due to its strong and flexible features, these materials have been used due to the ease of welding and inherent resistance to groundwater and common waste water treatment chemicals. There are now myriad of metal, plastic, asphaltic, and hydrophilic materials, with differing compositions that are utilized to stop water ingress through joints in concrete structures.

More About Waterstop PVC

In general, PVC waterstop acts as a continuous watertight diaphragm to prevent any flow of liquids in constructions joints which are subject to hydrostatic pressure. These materials are designed for expansion or contraction joint. In addition to this, it can also accommodate lateral and transverse movements which make it capable to fit the moving joints.

Furthermore, waterstop PVC are extruded from an elastomeric plastic material such as high-grade polyvinyl chloride, special resin and some chemical additives including plasticizers and stabilizers. The high material makes PVC waterstops unsurpassed with a variety of features and benefits as shown follow.

Features & benefits of Waterstops:

- High tensile strength.

- Superior elongation capacity

- Supreme inherent elasticity and durability

- High resistance to acids, ozone, seawater even diesel oil

- Not vulnerable to fatigue deterioration unlike metal or rubber

- Never discolor concrete

- No electrolytic action with surrounding metals

- Capable to withstand hydrostatic pressure

- Combat the expansion and shrinkage movement of the joints

- Capable to taking care of any deflection caused by the change in temperature

- Supplied in coils for easy handling with high flexibility

- Easy to install by tethering the outer flanges of the PVC waterstop to adjacent a reinforcing bars

Construction chemicals manufacturers always say that it is important that the waterstop is manufactured with quality raw materials, without defects. Many material types and profiles are available for different applications and conditions so the specifier should choose waterstops, preferably with manufacturer consultation, appropriate for all the joint conditions.

Are you looking for the right pvc waterstop for your project? At Corrotech Construction Chemicals, they offer various types of waterstops that help you create crack-free watertight concrete structures. For more detailed information regarding PVC waterstops and the right type of waterstop suited for your application, visit their website at https://www.mctuae.com/